Resin precision molding, One-stop service

Resin raw materials, Mold design, Prototyping and Mass production

One-stop development of resin molded products that require advanced technology

We provide an expert service for (1) raw material procurement, (2) design support, and (3) arrangement of processing plants for resin molded products.

We can support requests for small quantities of product that would require a lot of time and money if they were produced in-house. We support a global standard production system.

We can respond to the following needs

Looking for improvement in the production efficiency of precision molds.

Looking for new outsource channel for the development of new molds.

Looking for productions in Southeast Asia that produce the same quality as Japan.

Business

Plastic molds and One-stop service

We have extensive expertise in resin molded products, especially in the fields of medical and scientific equipment and electronic components. We provide one-stop service, from resin product design, mold design to raw material procurement and mass production.

-

Design Services

-

Technology and Development

-

Mold design and Manufacturing

-

Resin and Raw material procurement

-

Prototyping and Mass production

-

Secondary processing

-

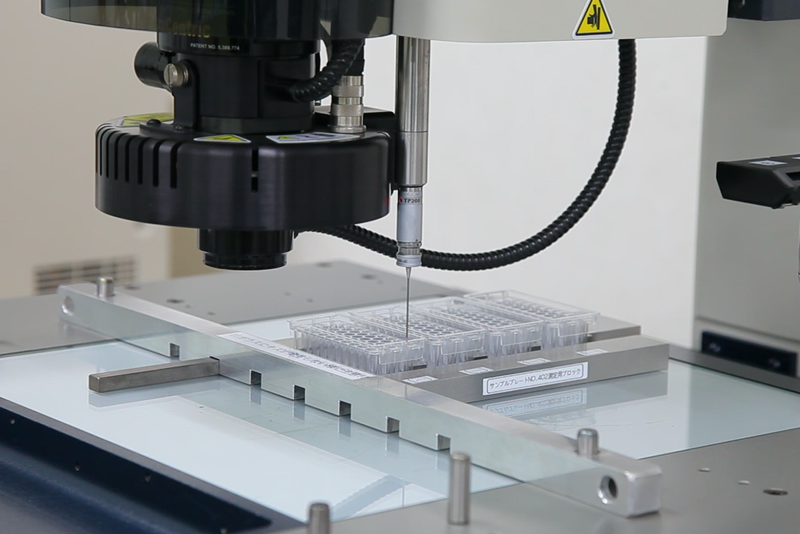

Inspection

Together with our reliable partners, Koji Chemicals Co. provides world-class, high-quality molded products.

Integrated production system

Kojo Chemicals Co.'s partner factories carry out everything from mold design, manufacturing to mass production of molds, secondary machining and assembly are also done in the company's own factories. This ensures smooth coordination between technicians and engineers. Not only that, it also reduces waste and loss significantly in the process of prototyping to mass production. This integrated production also makes it possible to offer total solutions without limiting the conditions for accepting orders for product and mold production.

Development Aid

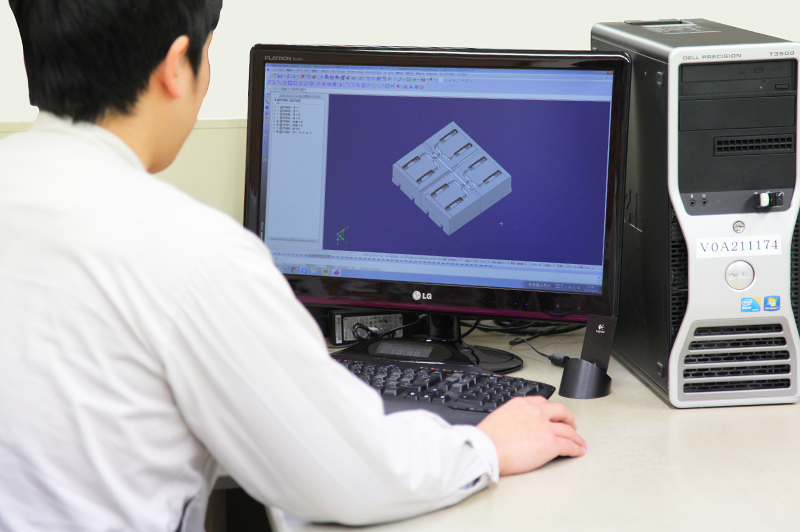

We support our customers' product design and development by making full use of 3D-CAD and flow analysis software based on our extensive experience and technology gained in mass production of molds.

In-house development of labor-saving electronic control equipment

We will develop various electronic control system equipment in-house, such as image inspection equipment and automatic assembly machines, and promote labor savings in mass-production plants. These will expand production capacity and make a significant contribution to improving the quality of products offered to customers and reducing costs.

Clean room (parts production, assembly inspection, primary packaging)

All areas involved in molding, inspection and assembly are clean rooms of class 10,000 to under 100,000, ensuring an environment suitable for the production of state-of-the-art medical and scientific equipment and precision electronic components.

Management System

With ISO 9001, ISO 14001 and ISO 13485 certifications, Koji Chemicals Co.'s partner factories develop and manufacture products with the global environment in mind and provide quality that satisfies customers.

Thorough quality and procedural controls

In order to implement the theory of upstream management, we have established a thorough quality control system for each production process and a quality assurance system that can handle mass production.

Features of Molding

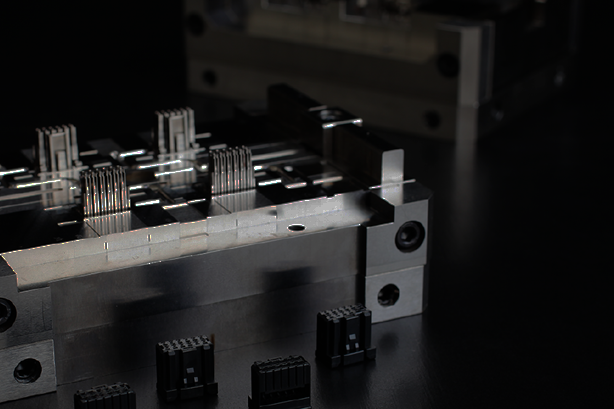

The mold design and fabrication line, which is staffed with experienced and skilled workers in key locations, enables us to respond immediately to mold modifications in a timely manner. In addition, the ability to smoothly develop products from the prototyping stage will provide our customers with even greater business opportunities.

The quality, cost and delivery time of the product are largely affected by the mold process, but the quality stability, production efficiency and life of the mold itself also depend on its manufacturing concept, design structure, component machining accuracy, material selection and heat treatment.

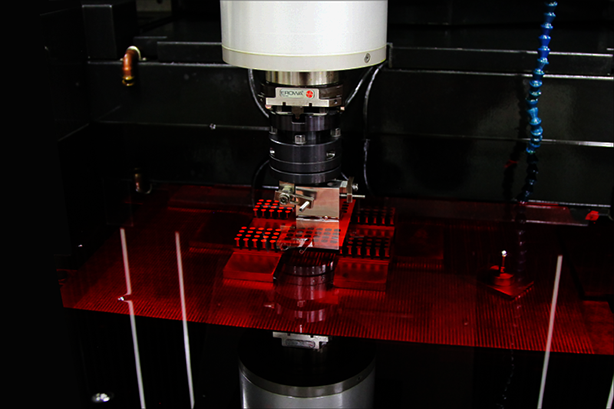

Realization of high-quality, ultra-compact molded products

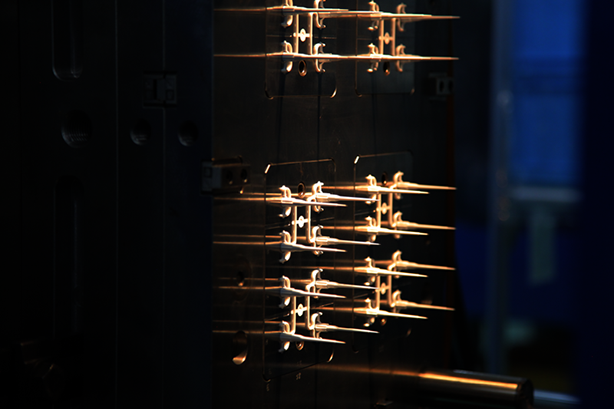

Mold manufacturing based on high-precision machining technology with a dimensional tolerance of less than 1 micron, such as grinding, enables the production of high-quality molded products. It can also produce ultra-small precision molded products weighing only 1/100 of a gram.

High productivity

The high accuracy of individual mold components allows for split-nesting structures and multiple molds. The split-nesting structure is also effective in preventing outgassing and extending the mold maintenance cycle. The small variation in the dimensions of each cavity also allows for the fabrication of a significant number of multiple-cavity molds, and these techniques enable highly productive mold fabrication.

Longevity

The high precision of part craftsmanship results in accurate positioning in the mold opening and closing, minimizes friction on sliding parts, greatly extending the life of the mold itself.

Resin Precision Molding Contract

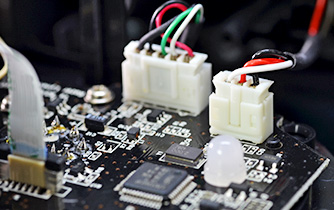

Precision molding of narrow-pitch connectors and other components for PCB mounting

KOJO CHEMICALS is capable of precision molding of connectors as small as a few microns, which are required for precision equipment such as electronic boards. We can also provide molding with high sliding properties and improved heat resistance for applications that require smooth and repetitive movement of parts in contact with each other.

Special molding (ETFE rotational molding)

Support for obtaining UN standard certification required for storage and transportation of dangerous goods, etc.

Special molding (injection molding of engineering plastics)

We select the most suitable material from a wide variety of plastic materials according to the purpose and application, and undertake the processing.

We are also able to offer other precision molding services to meet various needs.

Please feel free to contact us for a quotation or inquiry , even if you need a small amount.

Resin Materials We Handle

Sumitomo Electric Industries, Ltd. "Gunpla® " (oil-impregnated plastic)

A material in which a small amount of lubricating oil is uniformly dispersed in the base polymer. It is widely used in sliding applications due to its low friction coefficient and excellent wear resistance.

Application examples

Bearings for automobile brakes, gas pedals; sliders and electronic parts; bearings for air conditioners; various rollers, various gears, etc.

Sumitomo Electric Industries "Terralink® "(Electron Beam Irradiation Crosslinking Resin)

This is an engineering plastic part with improved fatigue strength by cross-linking the plastic with electron beam irradiation. It is increasingly replacing plastic parts due to its compactness and light weight.

Application examples

Teralink®S: Sliding parts such as gears, washers, sliders, etc.

Teralink®T: Enables optical design of lenses, etc.

Super engineering plastics, general-purpose engineering plastics, etc.

Super engineering plastics are highly functional materials that add strength and heat resistance to conventional plastics, as well as heat resistance and flame prevention.

Application examples

Automobiles, sensors, electrical and electronic parts, valves, pumps, heat-resistant food containers, aluminum substitute parts, etc.

PET, PBT, POM, Nylon, ABS, PS, etc.

There are resins with various properties and characteristics such as strength, electrical insulation, flame retardance, weather resistance, chemical resistance, and electrical insulation. We can propose products from various manufacturers according to the required application.

Application Examples

Food packaging, electrical and electronic parts applications, automobiles, electrical components, cabinets, gears, bearings, door wheels, pipes, clothing, TV and radio parts, containers, miscellaneous goods, etc.

Service Delivery

For precision molding of resin

-

—

01

Meeting

Submission of design drawings, selection of processing plant and raw material resin, etc.

-

—

02

Submission of quotation

We will prepare a quotation based on the contents of the meeting.

-

—

03

Mold production

We will make arrangements for the production of molds necessary for production.

-

—

04

Sample production

We will procure the raw materials and check the sample production.

-

—

05

Production and delivery

If there are no problems with the samples, we will mass produce and deliver them.

Request for Quotation

Please feel free to request a quotation, even for small quantities.

We will make arrangements for smooth and reliable molding.

If you have any questions, please feel free to contact us.